BWT & ENVIRONMENTAL SERVICES

BWT & ENVIRONMENTAL SERVICES

BWT Services

BWT Services

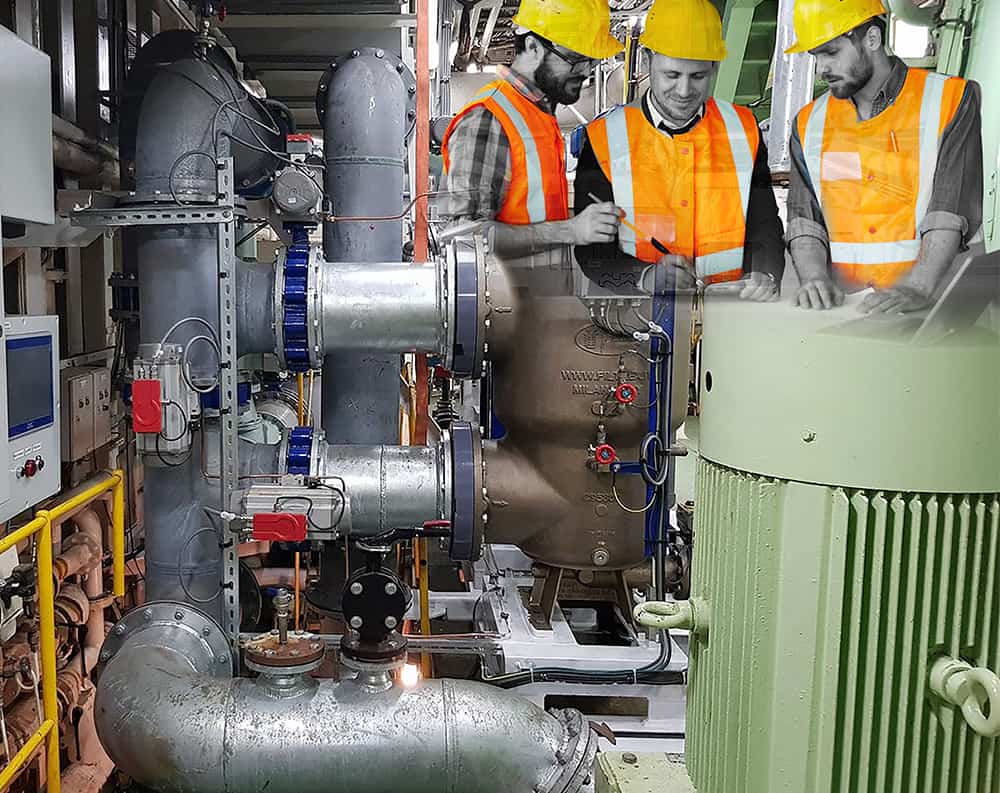

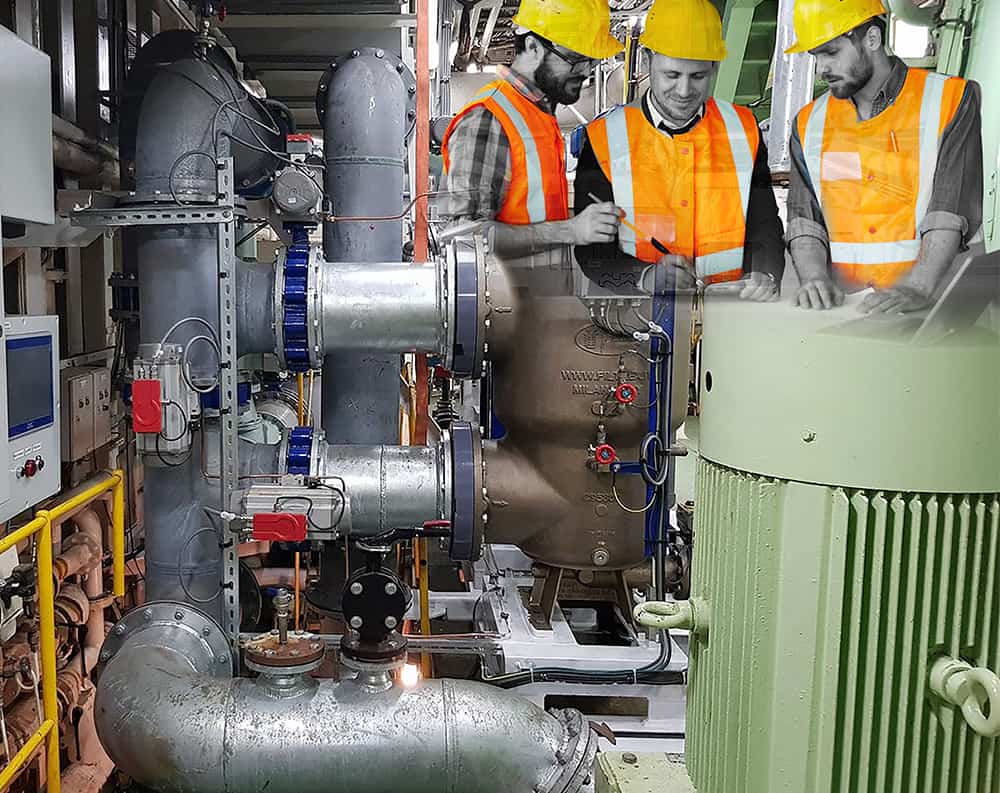

Our team has built extensive experience on Ballast Water Treatment (BWT)

![]() Team Experience

Team Experience

![]() Commissioning in Shipyard or during sailing & Aftersales: 15+

Commissioning in Shipyard or during sailing & Aftersales: 15+

BWT Services

![]() Commissioning Services

Commissioning Services

![]() Mechanical Installations:

Mechanical Installations:

Supervision for entire installation of BWT in shipyard or During sailing including provision of riding team for installation. Other than sea chest modification, entire job can be undertaken in sailing. The team has experience of various BWTs such as Tech Cross, Alpha Laval, DESMI, Blue Ballast, Headway etc

BWT Services

BWT Services

Our team has built extensive experience on Ballast Water Treatment (BWT)

![]() Team Experience

Team Experience

![]() Commissioning in Shipyard or during sailing & Aftersales: 15+

Commissioning in Shipyard or during sailing & Aftersales: 15+

BWT Services

![]() Commissioning Services

Commissioning Services

![]() Mechanical Installations:

Mechanical Installations:

Supervision for entire installation of BWT in shipyard or During sailing including provision of riding team for installation. Other than sea chest modification, entire job can be undertaken in sailing. The team has experience of various BWTs such as Tech Cross, Alpha Laval, DESMI, Blue Ballast, Headway etc

![]() Electrical Installation:

Electrical Installation:

![]() Entire control commissioning in shipyard or during sailing including electrical cable laying, termination, loop testing, integrating with shipboard controls & hydraulic systems. Prepare for presenting to OEM engineer for startup.

Entire control commissioning in shipyard or during sailing including electrical cable laying, termination, loop testing, integrating with shipboard controls & hydraulic systems. Prepare for presenting to OEM engineer for startup.

![]() Main switch board modifications for installing the new breakers or higher capacity breakers including the modification of bas bar or its extension.

Main switch board modifications for installing the new breakers or higher capacity breakers including the modification of bas bar or its extension.

![]() Supply Of Electrical Hardware: Provision of any control system as per the project requirements including starters/VFD panel to suit the new electrical motors.

Supply Of Electrical Hardware: Provision of any control system as per the project requirements including starters/VFD panel to suit the new electrical motors.

![]() Troubleshooting Services

Troubleshooting Services

![]() Ship Attendances: Our Service Team attend the ships for various troubleshooting in operating BWTs for any type of control equipment’s, rectifiers etc

Ship Attendances: Our Service Team attend the ships for various troubleshooting in operating BWTs for any type of control equipment’s, rectifiers etc

![]() BWT PCB Repair: We can repair any complicated PCB in our PCB Repair Lab in Mumbai.

BWT PCB Repair: We can repair any complicated PCB in our PCB Repair Lab in Mumbai.

![]() Troubleshooting Services

Troubleshooting Services

![]() Ship Attendances: Our Service Team attend the ships for various troubleshooting in operating BWTs for any type of control equipment’s, rectifiers etc

Ship Attendances: Our Service Team attend the ships for various troubleshooting in operating BWTs for any type of control equipment’s, rectifiers etc

![]() BWT PCB Repair: We can repair any complicated PCB in our PCB Repair Lab in Mumbai.

BWT PCB Repair: We can repair any complicated PCB in our PCB Repair Lab in Mumbai.

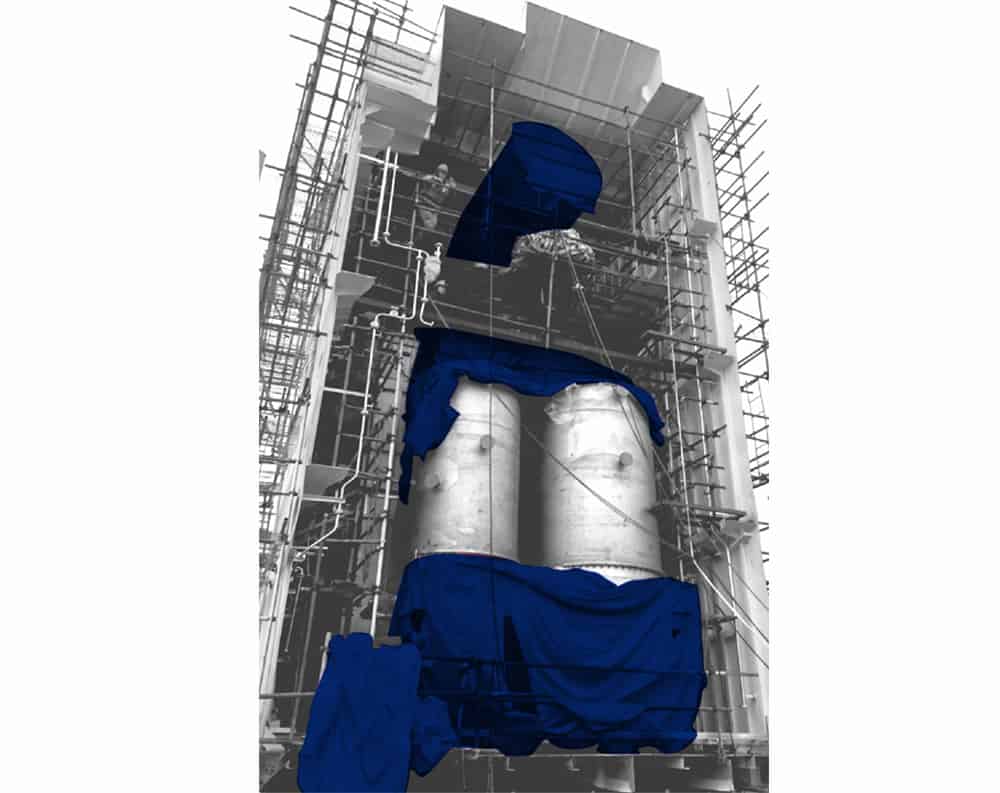

Scrubber Services

Commissioning Services

![]() Entire controls commissioning in shipyard or during sailing including electrical cable laying, termination, loop testing, VFD installation & setting including Sea trials with Class surveyor or by remote survey.

Entire controls commissioning in shipyard or during sailing including electrical cable laying, termination, loop testing, VFD installation & setting including Sea trials with Class surveyor or by remote survey.

![]() Main switch board modifications for installing the new breakers or higher capacity breakers including the modification of bas bar or its extension.

Main switch board modifications for installing the new breakers or higher capacity breakers including the modification of bas bar or its extension.

After Sales Services

![]() Troubleshooting: Troubleshooting any kind of PLC or control problems

Troubleshooting: Troubleshooting any kind of PLC or control problems

![]() CEMS Servicing: Servicing of complete CEMS, of various makes like Norske Analyse, SICK, Green instruments.

CEMS Servicing: Servicing of complete CEMS, of various makes like Norske Analyse, SICK, Green instruments.

![]() WWMS- Wash water monitoring system services of various makes like Green instruments, Chelsea Technologies, Sigrist etc

WWMS- Wash water monitoring system services of various makes like Green instruments, Chelsea Technologies, Sigrist etc

![]() Calibration Gas: Supply of scrubber calibration gas “ShipCalGas

Calibration Gas: Supply of scrubber calibration gas “ShipCalGas

![]() Inspections & Passivation: Scrubber internal inspection & Passivation services for any corrosion related issues.

Inspections & Passivation: Scrubber internal inspection & Passivation services for any corrosion related issues.

![]() Scrubber Overboard pipe inspection: Our inspection procedures are made in line with class requirements.

Scrubber Overboard pipe inspection: Our inspection procedures are made in line with class requirements.

![]() Scrubber Customized solutions: Pl review other section UGSCAN & UGSMC

Scrubber Customized solutions: Pl review other section UGSCAN & UGSMC

![]() Remote service support by our remote service platform.

Remote service support by our remote service platform.

Calibration Services

![]() We not only carry out overhaul of CEMs but also calibration of CEMs. Each CEMs has different working range and it is necessary to know the operating range for correct usage of the calibration gas.

We not only carry out overhaul of CEMs but also calibration of CEMs. Each CEMs has different working range and it is necessary to know the operating range for correct usage of the calibration gas.

![]() Entire system sensors, pressure gauges, temp gauges needs annual calibration which can be done either by physical presence or Remotely with our UGteck™ platform.

Entire system sensors, pressure gauges, temp gauges needs annual calibration which can be done either by physical presence or Remotely with our UGteck™ platform.

CII Intelligence Services

CII Intelligence Services

We guide you in achieving environment compliance and manage CO2 targets.

“Carbon Intensity Indicator” (CII) will become mandatory from the year 2023. Accordingly, the vessels will be classified into five different efficiency classes (A-E) and thereby the associated CO2 reduction targets will even become more stringent from year to year. Your ship may be complying initially but may drop to lower class latter. Hence you need to have your strategy in place to ensure future compliances & be competitive.

![]() Real Time Data & Intelligent Ship Performance Analytics:

Real Time Data & Intelligent Ship Performance Analytics:

Our system developed for Performance monitoring which provides you real time calculations of not only CII but also real time carbon generated between a period. By doing this you know where you stand and what measures you need to take. Pl read ship performance analytics for details.

![]() Soft Starter To VFD Conversion:

Soft Starter To VFD Conversion:

Many of the clients are working on changing the fixed drive pumps to VFD to save on fuel consumptions and reduce CII values. We provide end to end solution

![]() VFD calculations for carbon saving & Return on Investments.

VFD calculations for carbon saving & Return on Investments.

![]() VFD Design & Class approval

VFD Design & Class approval

![]() VFD Supply & Installation

VFD Supply & Installation

![]() PLC system design for automatic operation of VFD

PLC system design for automatic operation of VFD

No need to go to big brands & hefty prices while we provide you entire system from reputed VFD makers & our PLC based system from makers like Siemens, Schneider etc

On demand we can provide you customized real time displays.

![]() Engine Power Limitations:

Engine Power Limitations:

It will require a control unit for calculating and limiting the power transmitted by the shaft to the ship’s propellers, as well as sensors for measuring torque and rotational speed and a data recording and processing device.

Whereas for modern engines have electronic control and the means of limiting such equipment (or accessing the power reserve) is via a fuel index limiter linked to a password, which can electronically lock the fuel index or directly limit power in the engine’s control system. On the other hand, a mechanically controlled engine will be restricted with a sealing device that can physically lock the fuel index, using a mechanical stop screw sealed by wire or an equivalent device with a governor limit setting.

EEXI Consultancy

EEXI Consultancy

We are offering below scope of work in EEXI/EEDI compliance.

Calculate attained EEXI and Required EEXI for the existing ship.

If the attained EEXI is less than or equal to the Required EEXI then apply for IEEC certification to the class.

If the attained EEXI is more than the Required EEXI then we will suggest appropriate improvement measures.

Engine Power Limitations: Study on Engine Power Limitation or Shaft Power Limitation

Estimation of speed loss and improvement in EEXI value based on Engine power limitation.

Study on the EEXI improvement due to fuel change to LNG.

Study on increase in deadweight for EEXI compliance.

Analysis on the use and type of Energy Efficiency Device on the given vessel.

Prepare the EEXI Technical File

The ship speed (Vref) for EEXI calculation should be obtained from the simple formula, the tank test results or CFD analysis

![]() Simple Formula: The simple formula takes a 5% margin and hence it is worst option.

Simple Formula: The simple formula takes a 5% margin and hence it is worst option.

![]() Tank test model: Tank test model is not easy mean as require documents for ship propulsion performance and tank test reports.

Tank test model: Tank test model is not easy mean as require documents for ship propulsion performance and tank test reports.

![]() CFD Analysis: Hence new CFD analysis is carried out for estimate of power curve

CFD Analysis: Hence new CFD analysis is carried out for estimate of power curve

We provide the following services

![]() CFD analysis of hull without energy efficiency device

CFD analysis of hull without energy efficiency device

![]() CFD analysis of hull with energy efficiency device fitted on the hull

CFD analysis of hull with energy efficiency device fitted on the hull

![]() EEXI Technical File (as per CFD analysis)z

EEXI Technical File (as per CFD analysis)z

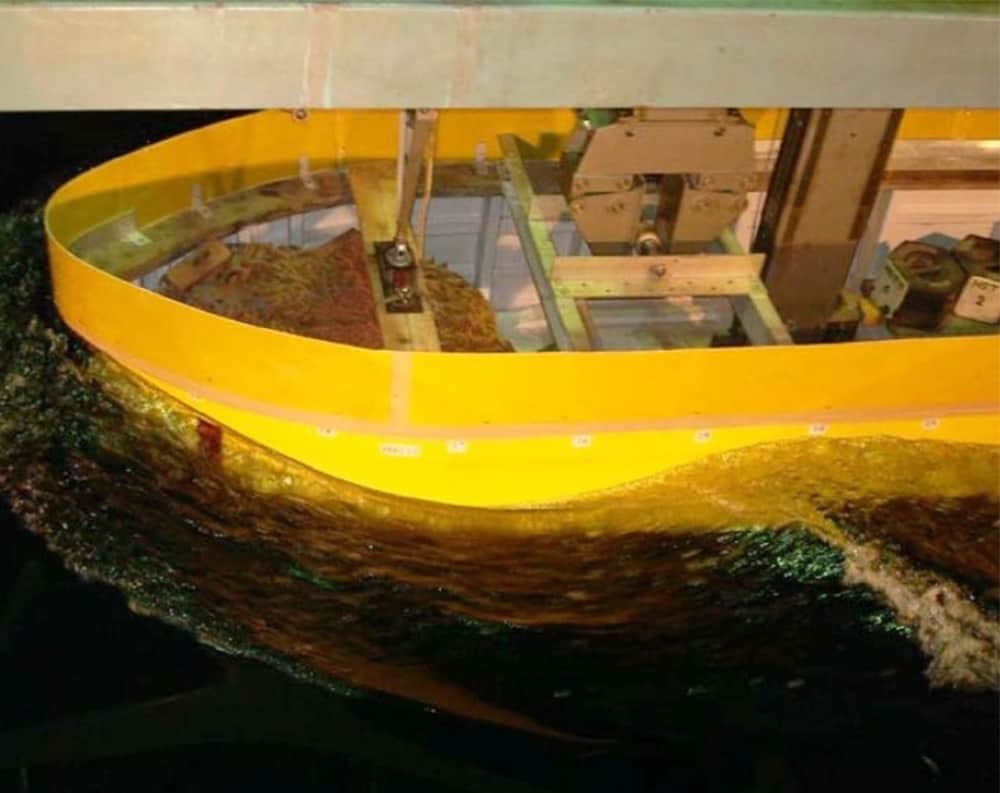

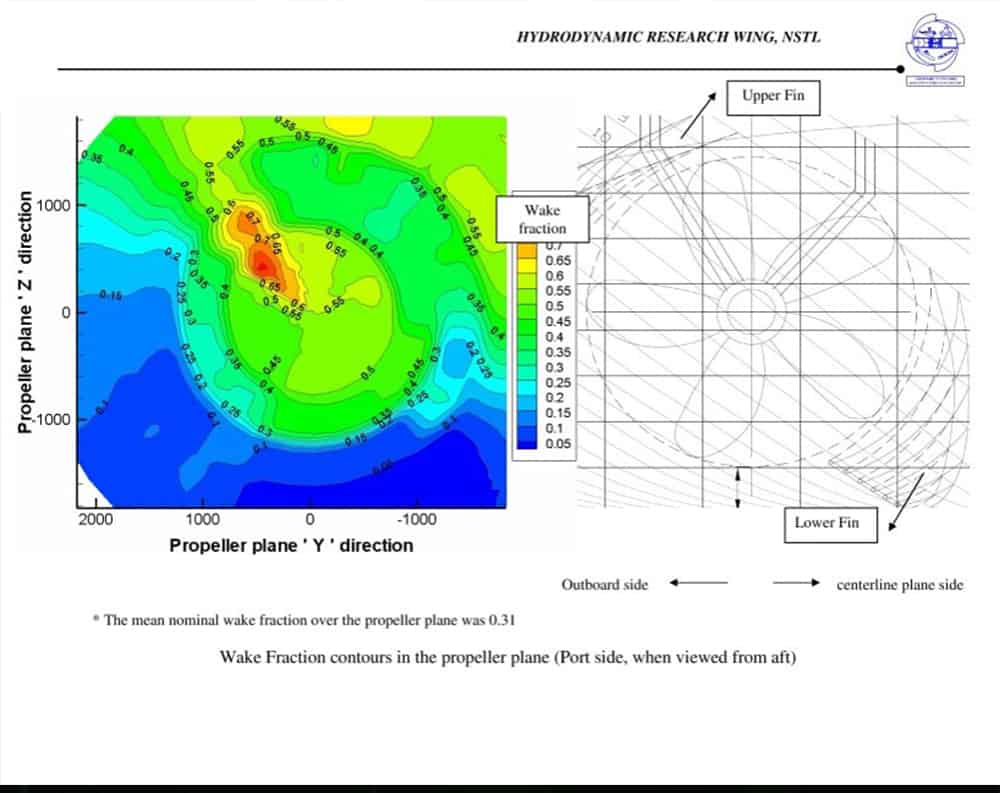

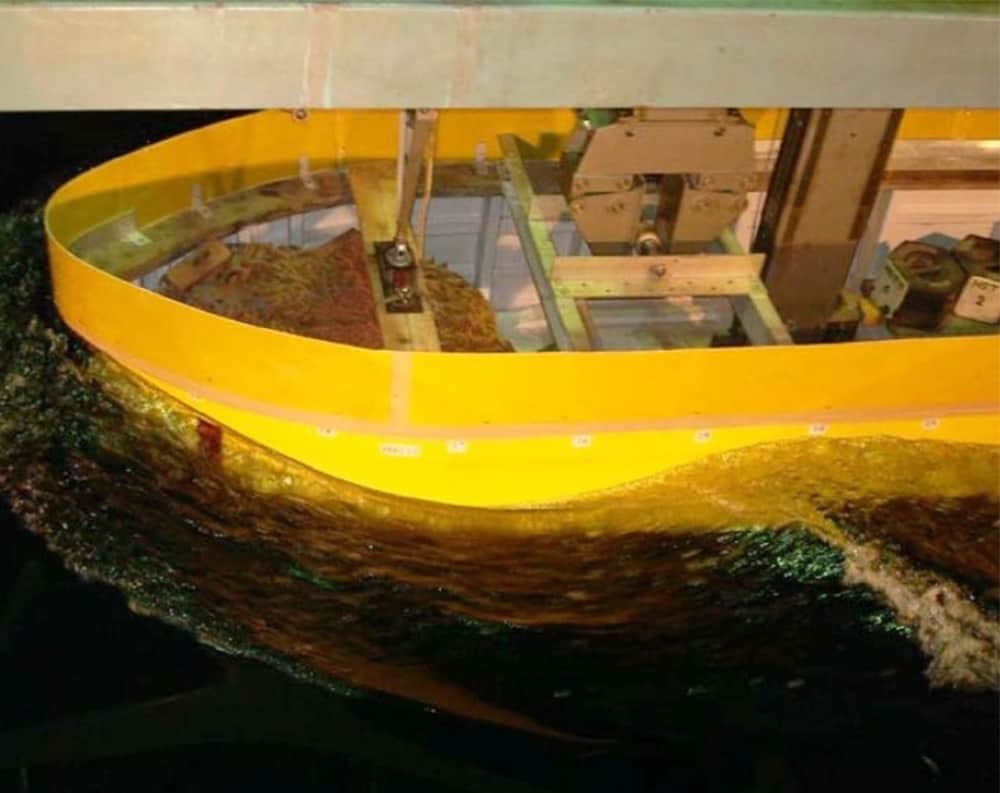

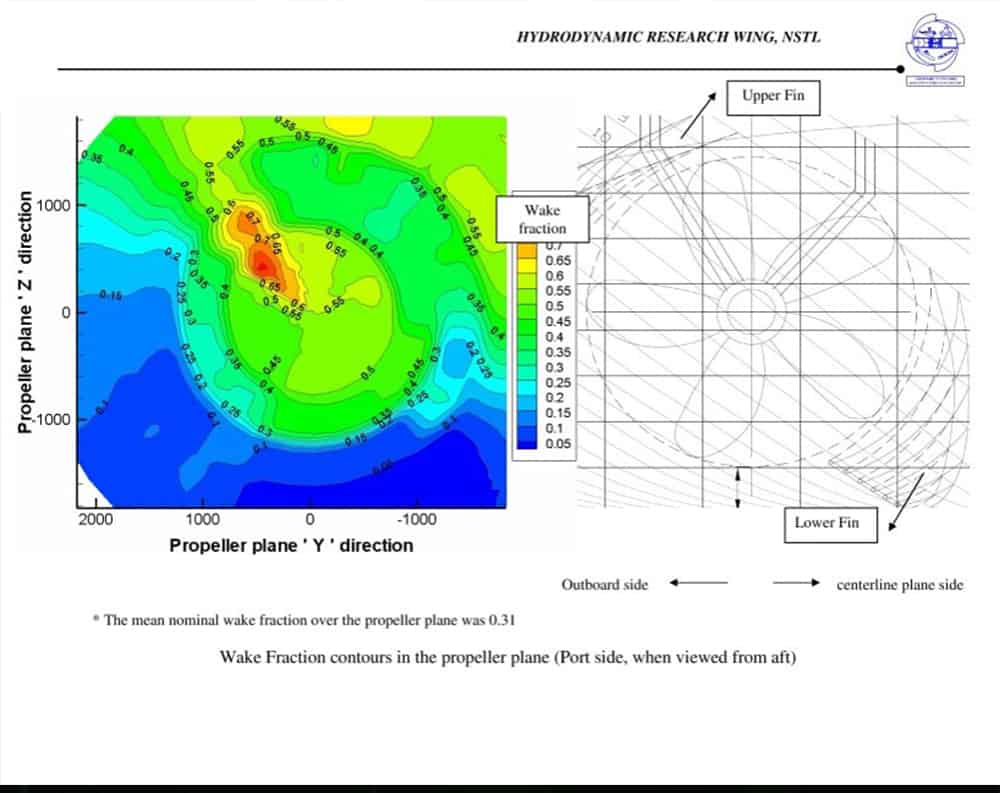

Case Study: Experience on improving the performance of TSHD

One TSHD performance was improved from poor to very good with following process

![]() Vibration analysis

Vibration analysis

![]() Model building & testing

Model building & testing

![]() CFD analysis

CFD analysis

![]() Propeller redesigning

Propeller redesigning

![]() Fitting of 8 Fins on stern part of vessel to allow more water to propeller

Fitting of 8 Fins on stern part of vessel to allow more water to propeller

Case Study: Experience on improving the performance of TSHD

One TSHD performance was improved from poor to very good with following process

![]() Vibration analysis

Vibration analysis

![]() Model building & testing

Model building & testing

![]() CFD analysis

CFD analysis

![]() Propeller redesigning

Propeller redesigning

![]() Fitting of 8 Fins on stern part of vessel to allow more water to propeller

Fitting of 8 Fins on stern part of vessel to allow more water to propeller