CRANE SERVICES

CRANE SERVICES

We provide wide range of Crane Repair services to clients in India & International. Our Crane service management system is certified by DNV.

Our Services

Our Services

Troubleshooting

Overhauling, Repairs & UpGrades

Crane Health checkups

Port support services

Implementing PMS services

IOT based

upgrades.

Troubleshooting

Our technical team who carries expertise for maintenance of cranes internationally for numerous years are available to provide troubleshooting.

Electrical faults such as tripping, Problem with slip rings, Electronic controls, Drives, PLC, communications, encoders and contactors issues.

Hydraulic fault trouble shooting & tracing fault with valves, motors, oil circuits etc

Troubleshooting

Our technical team who carries expertise for maintenance of cranes internationally for numerous years are available to provide troubleshooting.

Electrical faults such as tripping, Problem with slip rings, Electronic controls, Drives, PLC, communications, encoders and contactors issues.

Hydraulic fault trouble shooting & tracing fault with valves, motors, oil circuits etc

Overhauling, Repairs & UpGradesRepairs

- Hydraulics pumps and valves servicing.

- Winches, gearbox & motors maintenance.

- Electrical Switchgear annual maintenance like starters, breakers, Slipring unit Maintenance

- PCB repairs up to chip level at our state-of-the-art PCB Lab @Mumbai.

Reconditioning of Hydraulic motors

Reconditioning of Hydraulic motors

- In case you have below damaged items, you can land with us and we shall return you after reconditioning & testing with condition similar like new. We have standard procedures for reconditioning. Our reconditioning management systems are approved by DNV. Reconditioning cost will be max 60% of new motor. We shall sea freight to your designated port.

- If you just need overhaul with your spares, let us know and we can provide you spares as well.

- Other than hydraulic motors, you can land Gear boxes, Electric motors, Sheeves etc

Crane Electrical & Controls Upgrades

Crane Electrical & Controls Upgrades

In case your PLC is damaged and do not have support from OEM, look at us. Pl, review our PLC service. We can upgrade your controls and PLC.

We also assist owners for overseeing crane repairs in shipyard at nominal charges.

Crane Health checkups

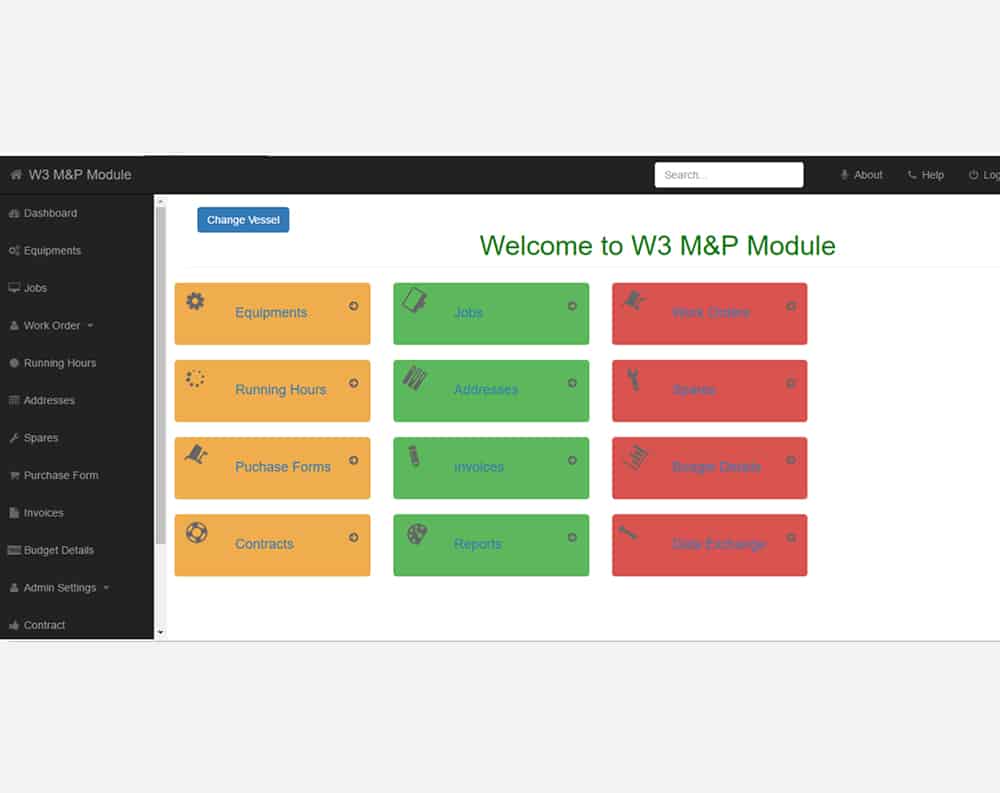

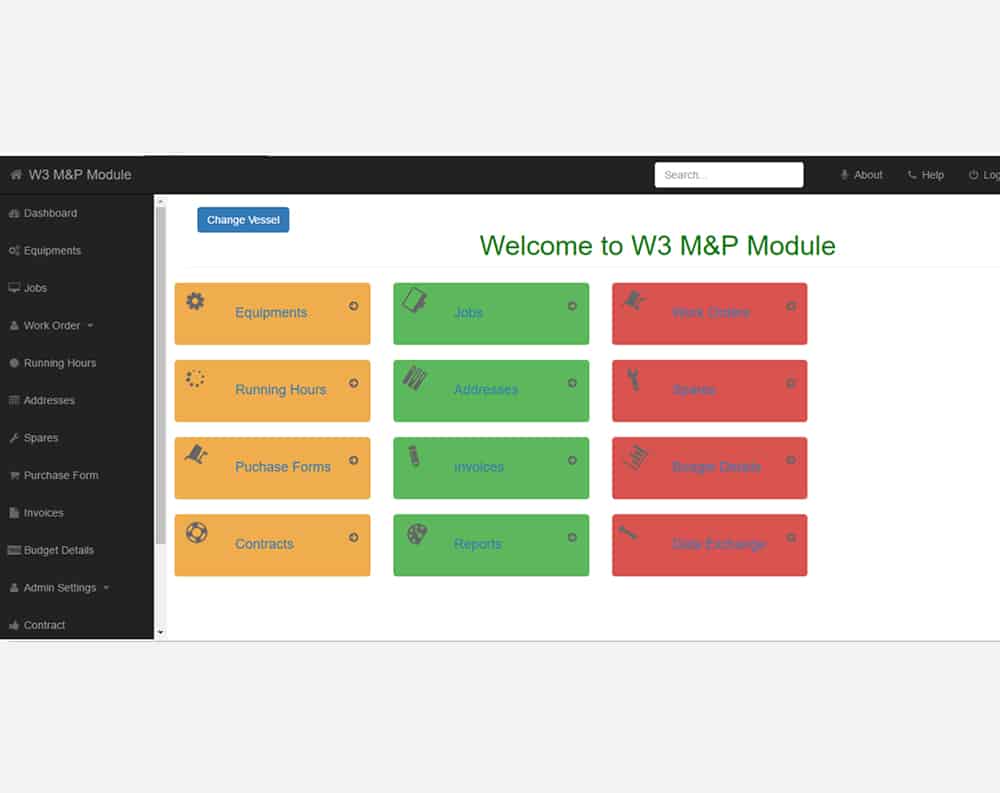

Major losses occur due to downtime due failures. Our routine inspection guided by our proprietary digital platform UGteck™ from which you can export checklist based on our experience factor will ensure that you have clarity on the health of your crane. Based on same we provide the recommendations on what is critical to be addressed immediately and what can be differed till major planned repairs along with spare parts requirements.

UGteck™ will generate jobs with real time collaboration till completed. This is to ensure that your cranes are always up & running.

- Hydraulic pump & crane performance assessment.

- Condition of hydraulic valves, motors, hoses, and fittings.

- Visual inspection of wear & tear components such as sheaves (wire grooves, bearing conditions, greasing condition), Hooks

- Wire conditions.

- Rocking test

Crane Health checkups

Major losses occur due to downtime due failures. Our routine inspection guided by our proprietary digital platform UGteck™ from which you can export checklist based on our experience factor will ensure that you have clarity on the health of your crane. Based on same we provide the recommendations on what is critical to be addressed immediately and what can be differed till major planned repairs along with spare parts requirements.

UGteck™ will generate jobs with real time collaboration till completed. This is to ensure that your cranes are always up & running.

- Hydraulic pump & crane performance assessment.

- Condition of hydraulic valves, motors, hoses, and fittings.

- Visual inspection of wear & tear components such as sheaves (wire grooves, bearing conditions, greasing condition), Hooks

- Wire conditions.

- Rocking test

- Cutoffs & safeties

- Electric motor condition & Insulation test.

- Electrical controls conditions

- LO can be landed with us for testing.

Port Support services:

We can provide customized support during cargo Operations to attend to any trouble during cargo operation at a very nominal rate This will ensure sudden breakdowns are attended and minimum downtime.

KYC- Know your cranes

Planned maintenance Services.

Based on our Report, our extensive in-house experienced team can advise major maintenance & spares requirement and can implement our planned maintenance system for cranes.

Planned maintenance Services.

Based on our Report, our extensive in-house experienced team can advise major maintenance & spares requirement and can implement our planned maintenance system for cranes.

Continuous health monitoring dashboard

With our smart upgrades kit, with various sensors to measures the health of the crane and record operational status with analytics to improve on discharging rate.

We provide PLC & SIM based system which can provide continuous health condition of the ship cranes over IOT to your office on smart phones / web and keep you appraised of the health with lesser reliance on ship staff.

The date can be provided on data logger with the provision to compare the performance trend.

Such data is helpful in ensuring the cranes are running at top speed and drop in performance is immediately addressed rather let it affect the cargo operation speed.