900.101- Musasino Float type Gauging problems & advice

Every superintendent deals with these issues during lifecycle of the ship. While it is a reputed brand with wide service network however like any other equipment, dealing with equipment brings own sets of problem. Mostly on older ship owners are always in a fix how much to spend on maintenance and are in fix how to go about resolving this.

Float Type Level Gauge with built-in tank pressure monitoring and tank temperature sensors. Some of them have Local indicator and some have only in control room where a panel is provided for display. At the top of the cargo tank is provided with various signal outputs (PCBs).

Following are main problems

Cargo tank level not shown in CCR and Local indicator.

![]() Float: Check the float condition for any damage and its floating. This can be carried only by man entry for which gas freeing is required. The level can be moved by a rope tied up and move the float up and down. If the readings either locally or at CCR are corresponding with the float, then it is Float issue. The usual thing is the replace the float however it can be refurbished also in our service Lab.

Float: Check the float condition for any damage and its floating. This can be carried only by man entry for which gas freeing is required. The level can be moved by a rope tied up and move the float up and down. If the readings either locally or at CCR are corresponding with the float, then it is Float issue. The usual thing is the replace the float however it can be refurbished also in our service Lab.

![]()

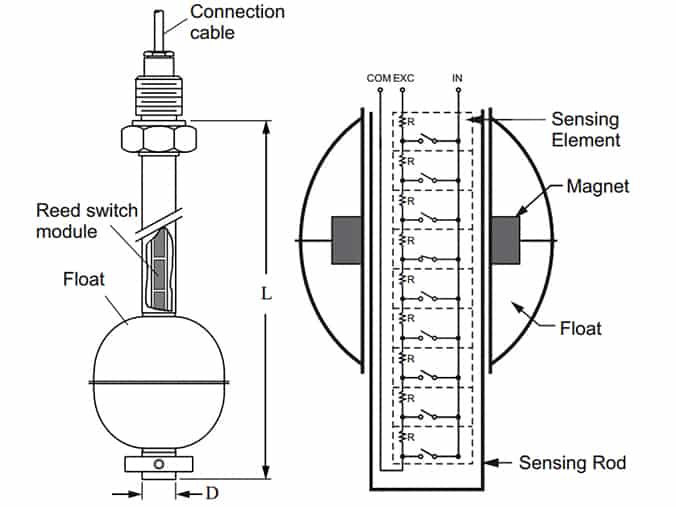

Level Sensor: If the Float is moving but the reading is still not changing, Level sensor could be defective. If the local display is provided same to be checked else check the sensor supply voltage should be around 5-volt dc and output signal should be 0- 5-volt dc as per tank level on tank top. The sensors are intricate part and usually ship is required to be renewing same with new one. The sensors is a

long rod which has series of Reed switches having an outside float which has magnet. As the float moves up and down, the resistance changes accordingly and hence the level is measured.

![]()

Repair Options of Sensors: The new is expensive and at times the owners can look at option of repairing them which can be sent to our service lab for thorough checking and repairing if repairable.

![]() Barrier: Check the tank level signal in CCR before and after barrier, should be 0-5 volt dc as per tank level, if output signal on tank top is ok and not proper at barrier input then

Barrier: Check the tank level signal in CCR before and after barrier, should be 0-5 volt dc as per tank level, if output signal on tank top is ok and not proper at barrier input then

cable from CCR Console to tank top be broken needs to be replaced. If signal on tank top and at barrier input is ok and not proper at barrier output, then barrier is defective and needs to be replaced.

![]() Check the indicator device id is correct and replace with another working indicator if possible.

Check the indicator device id is correct and replace with another working indicator if possible.

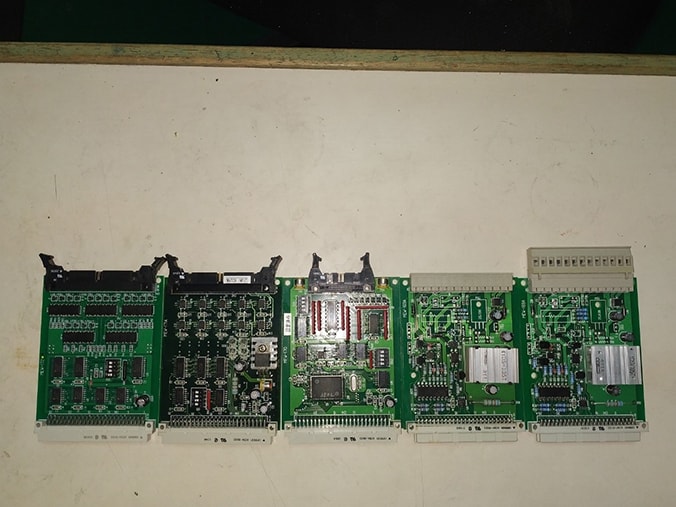

![]() If the tank signal after barrier is ok and level is not shown, then the input card might be defective needs to be replaced. It is good practice to keep spare PCBs. You can land the defective PCBs in our service Lab for refurbishing.

If the tank signal after barrier is ok and level is not shown, then the input card might be defective needs to be replaced. It is good practice to keep spare PCBs. You can land the defective PCBs in our service Lab for refurbishing.

Cargo tank level jumping/ Skipping the reading or Erratic & unreliable

![]()

Check the float is floating straight and not tilted. Could be checked once the cargo tank is gas free.

![]() Level sensor might be damaged. Check the sensor supply voltage should be around 5 volt dc and output signal should be 0- 5 volt dc as per tank level on tank top.

Level sensor might be damaged. Check the sensor supply voltage should be around 5 volt dc and output signal should be 0- 5 volt dc as per tank level on tank top.

Cargo tank high (95%) and high- high (98%) alarm.

![]() Check the supply voltage on tank top. And output signal. If not proper sensor needs to be replaced.

Check the supply voltage on tank top. And output signal. If not proper sensor needs to be replaced.

![]() When the alarm is simulated using magnet the voltage should drop. If output signal on tank top is ok and not proper at barrier input, then cable from CCR console to

When the alarm is simulated using magnet the voltage should drop. If output signal on tank top is ok and not proper at barrier input, then cable from CCR console to

tank top be broken needs to be replaced. If signal on tank top and at barrier input is ok and not proper at barrier output then barrier is defective and needs to be replaced.

![]() Check whether the high / high-high alarm indication on level indicator and relay output (contact) in indicator is active while the alarm is simulated. If not then relay inside level indicator is defective needs to be replaced.

Check whether the high / high-high alarm indication on level indicator and relay output (contact) in indicator is active while the alarm is simulated. If not then relay inside level indicator is defective needs to be replaced.

![]() If the relay contact inside the level indicator is ok then the alarm logic for 95% and 98% needs to be checked.

If the relay contact inside the level indicator is ok then the alarm logic for 95% and 98% needs to be checked.

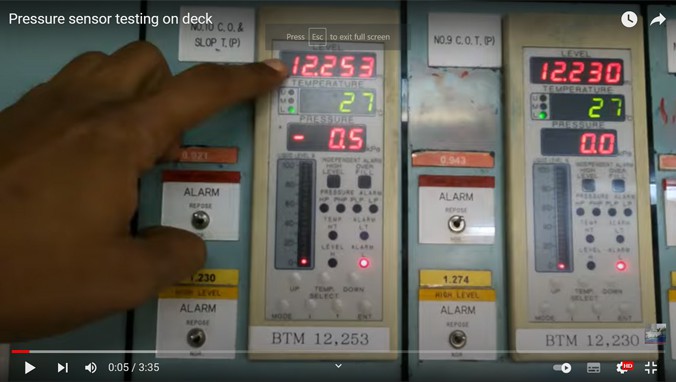

General guidelines- There are two set of system. The tank level guaging system and overfill alarm are different set of systems. On the panel there is Ullage, temp and pressure of each tank.

The sensors which are fitted on each tank for pressure or vaccum must be checked that they are funcitioning. The function test can be carried out by the kit which is provided onboard which basically is a syringe. This allows only to check that with change in pressure OR vaccum the readings are changing. The guidelines for same can be found in manual or our form 900.102

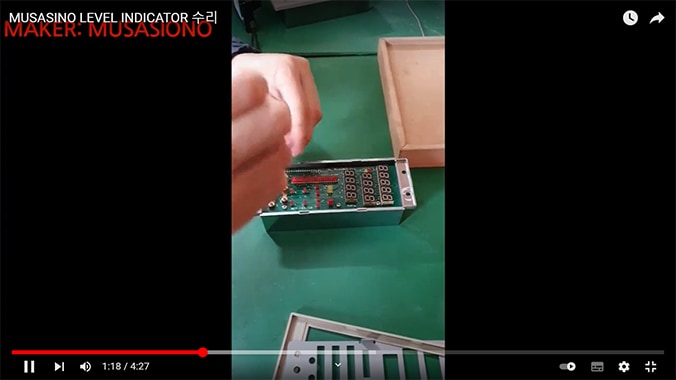

In case the display indicator is defective, you can land with us for possible repair. For programming of the indicator, we need the setting which possibly be avilable with the client from makers.

Sorry, the comment form is closed at this time.